In March 2024 MCA were engaged to complete the task of replacing level 5 to level 1 steel work in the shaft at a local mine site after the steel work was due for end-of-life replacement. This work was to be completed during the longest duration shut down at the mine of over 550hrs.

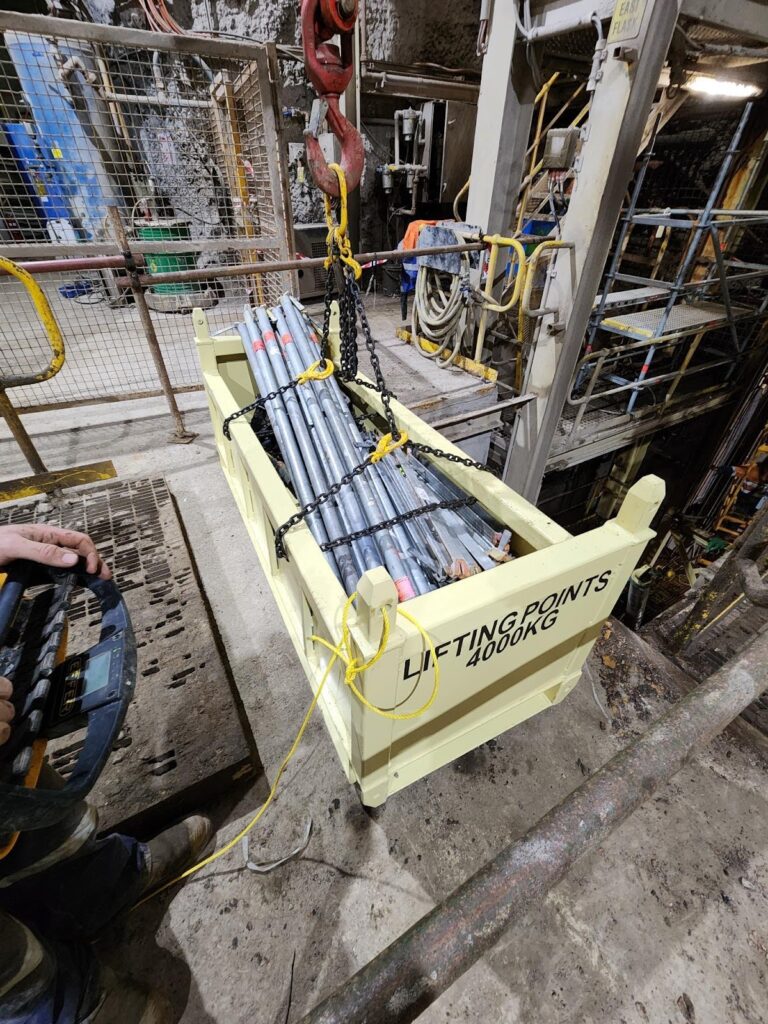

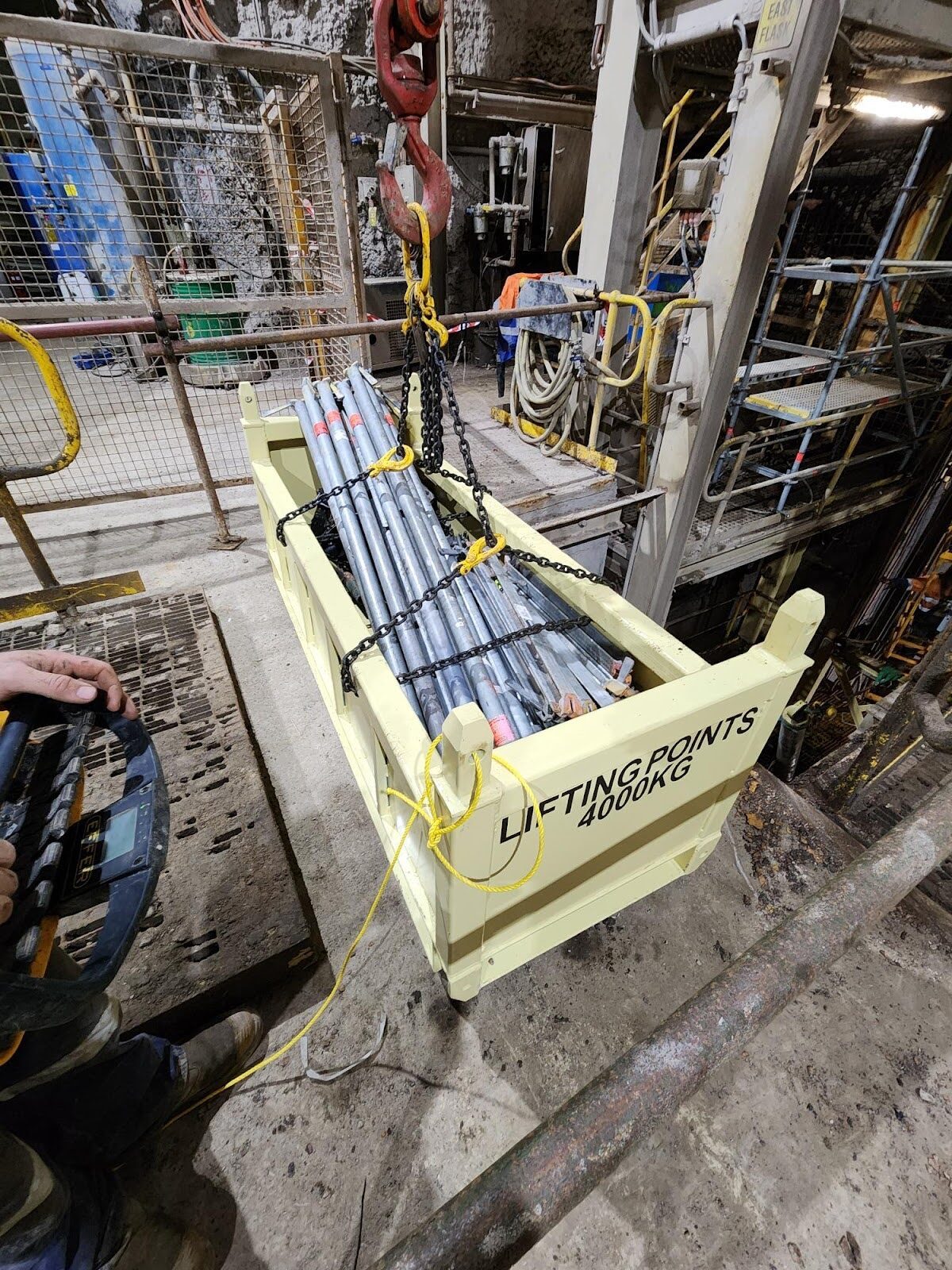

MCA completed 1500hrs of pre works to prepare for the shut including use of MCA’s vehicles, truck and franna crane underground. This equipment was also used during the shut for transporting of steel work in and out of underground. MCA also worked close with the Owner’s team to develop and fine tune, methodology, schedule, lift plans, specific training packages, level 2 risk assessment, ITPs and JHAs in preparation of the outcome of no injuries during this work.

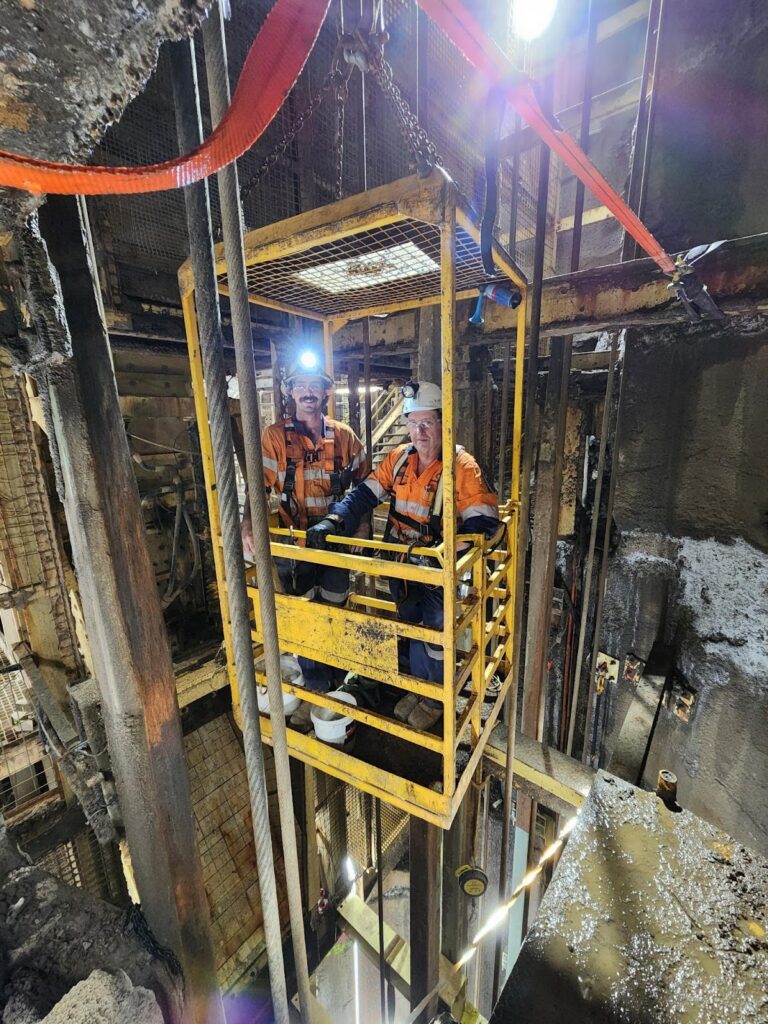

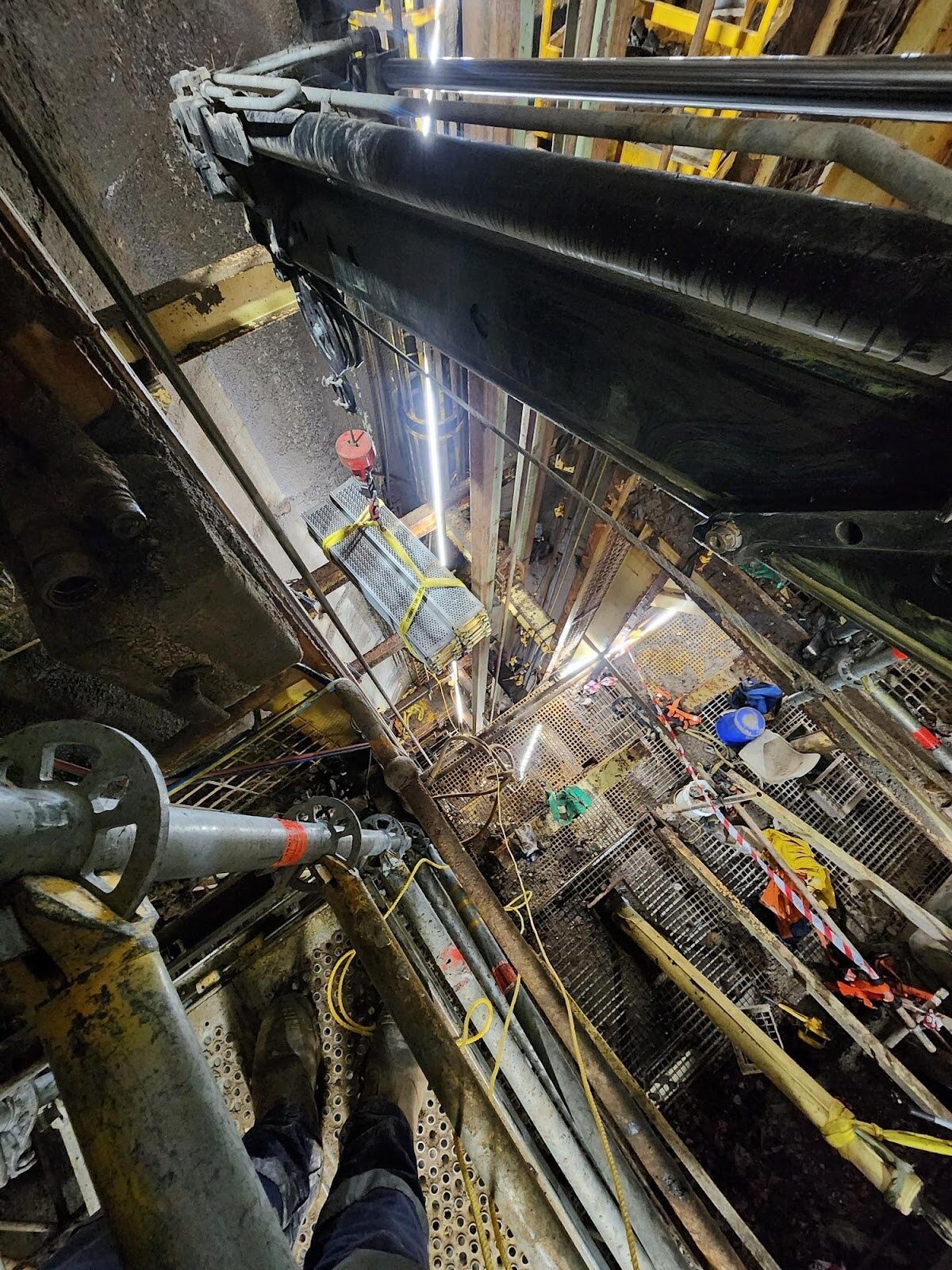

MCA provided more than 4000 hours of specialized labour, including boilermakers, fitters, operators, and crane drivers throughout the 500-hour shutdown. Every shift of the shutdown involved high-risk work. A major risk for the work front was having three cranes within the shaft at key times to ensure works was completed and in a safe and efficient manner.

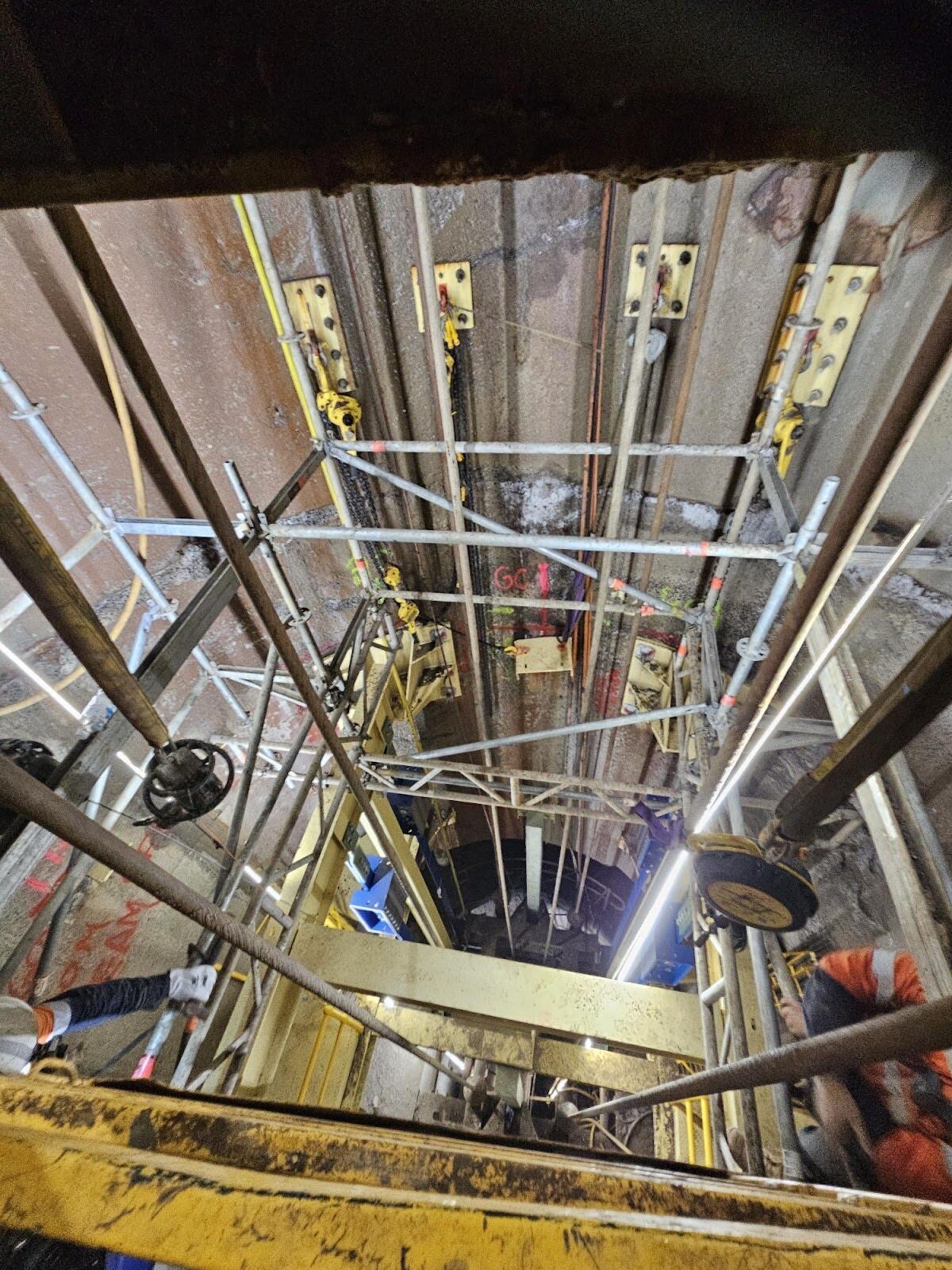

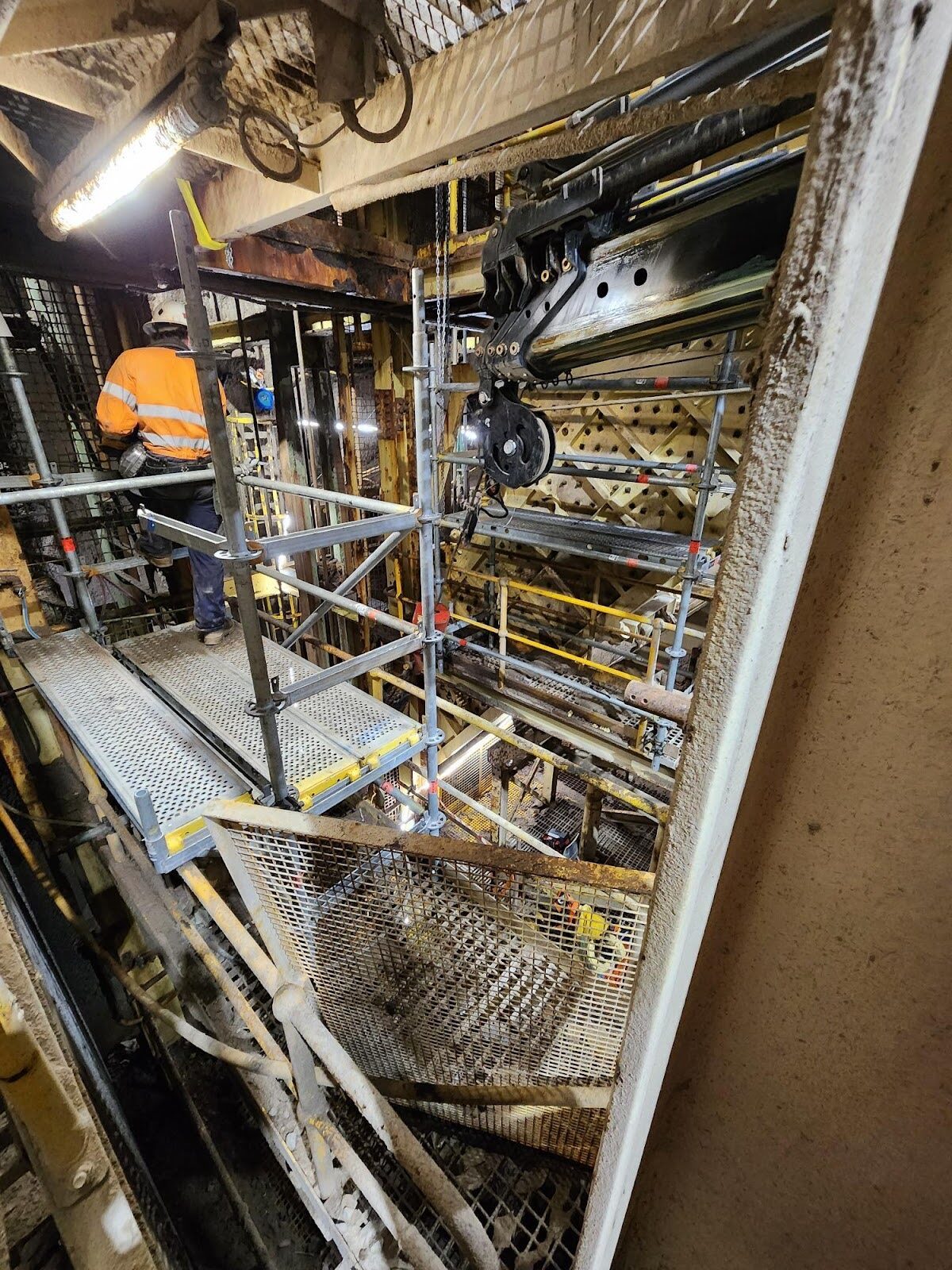

A win was the use of an Effer Crane mounted in the flask area underground. (See Image 4) This crane was purchased by the mine specifically for this project and it had proven advantages within the tight space within the shaft.

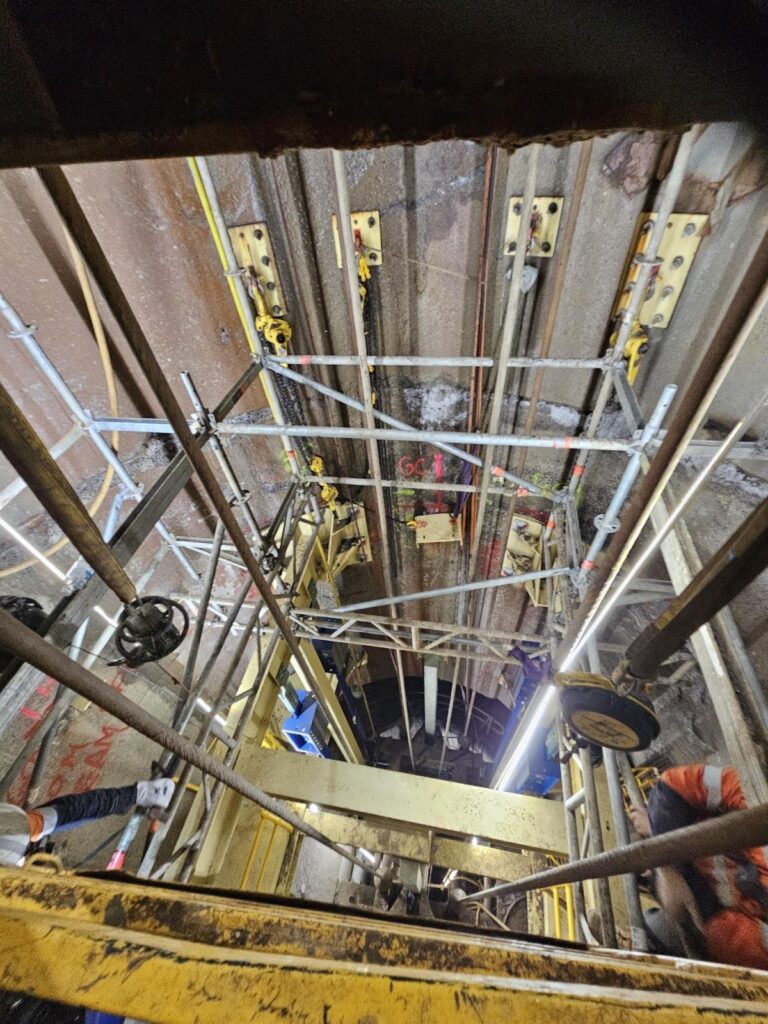

Scaffolds were constructed from each level in order to access the subsequent level during the removal and replacement of steel work. Airleg drilling and bolting were done from the scaffold for all wall brackets in the shaft that supported the steel construction.

During this time, MCA also serviced with labour and equipment the two other planned outages onsite, UG for 100 hours and a module 1 outage in the ore processing department.

The mine’s leadership team, had positive feedback to MCA with the attention to detail, quality of people and the commitments to safe operations. This has position MCA well for the next stage of the project of the further replacement of the lower level’s 7-12 and ongoing shaft maintenance for the future.